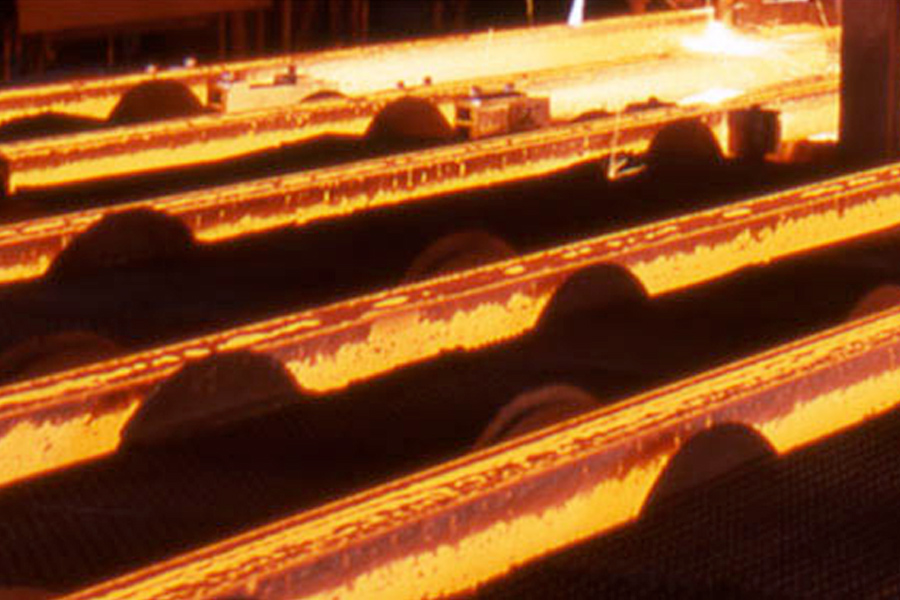

The steel industry utilises rubber rollers throughout the steel production process to perform certain task; these rollers are covered with rubber compounds specially formulated for specific applications that are compatible to the many process requirements. Key essential properties are chemical, temperature, abrasion, friction and release; usually steel roller applications will involve a combination of these characteristics.

Bridle & Guide Rollers

TrenseMaster I 75-90 Shore A

Excellent abrasion and cut resistance with low heat build up

TrenseMaster II 60-90 Shore A

Improvement over standard XN series

TrenseMaster III 40-95 Shore A

Exceptional abrasion resistance

TrenseMaster IV 60-80 Shore A

Excellent physical and abrasion properties

Anvil Rollers

BoltMaster I 45–95 Shore A

Good in aggressive hot aqueous media. Outstanding hardness stability, abrasion resistance & resilience

TrenseMaster IV 60-80 Shore A

Excellent physical and abrasion properties

Deflector Rollers

VeerMaster I 45–95 Shore A

Exceptional wear and cut resistance, with outstanding load bearing & temperature resistance

VeerMaster II 65–90 Shore A

Good balance of chemical properties and chemical resistance

Hold Down Rollers

VeerMaster I 45–95 Shore A

Exceptional wear and cut resistance, with outstanding load bearing & temperature resistance

VeerMaster II 65-90 Shore A

Good balance of chemical properties and chemical resistance

VeerMaster III 60-90 Shore A

Snubber Rollers

CanMaster 40-90 Shore A

Specially formulated for enhanced chemical resistance to aromatic solvents

Squeegee Rollers

VeerMaster I 45–95 Shore A

Exceptional wear and cut resistance, with outstanding load bearing & temperature resistance

VeerMaster III 60–90 Shore A

VeerMaster III 65–90 Shore A

Good balance of chemical properties and chemical resistance

Steering Rollers

BoltMaster I 45–95 Shore A

Good in aggressive hot aqueous media. Outstanding hardness stability, abrasion resistance & resilience

TrenseMaster II 60–90 Shore A

Improvement over standard XN series

TrenseMaster I 75-90 Shore A

Excellent abrasion and cut resistance with low heat build up

Hot Water Wringer Rollers

BoltMaster I 45–95 Shore A

Good in aggressive hot aqueous media. Outstanding hardness stability, abrasion resistance & resilience

TrenseMaster III 60–90 Shore A

Improvement over standard XN series

Applicator Rollers

CoatMaster I 45–70 Shore A

For use in Keytones or Esters

CoatMaster II 45–70 Shore A

Outstanding abrasion properties

Embossing Rollers

EmbossMaster I 70–90 Shore A

Excellent abrasion resistance and resilience

EmbossMaster IV 70–90 Shore A

Excellent abrasion resistance